Case AVR: optimizing yield and size of potatos with stereovision and AI

AVR potato size measurement system

1. The big picture: Increasing demands in automotive & manufacturing

AVR Machinery is a leading Belgian manufacturer of machinery for potato cultivation.

The company's green harvesters are a well-known sight on potato fields worldwide. Vintecc supported AVR with the development of an innovative potato size measurement system installed on AVR's flagship Puma 4.0 harvester. Vintecc guided development from prototype to a production-ready system, enabling AVR to minimize time to market.

AVR has made it its mission to help customers store a higher percentage of sellable crops with less input. The company is leveraging technology to achieve this goal. For years, various yield measuring systems have been available for potato harvesters. However, one of the disadvantages of these systems is that they only provide a weight value. Since these systems cannot distinguish between potatoes and soil clods or stones, they give an inaccurate view of the yield.

A more relevant tool is potato size measurement. Size (width and length) is an important quality parameter in the potato cultivation industry, because it directly impacts market value, with different sizes preferred for various uses (such as seed potatoes, chips, fries, or fresh market sales). Consistent sizes also ensure efficient processing, packaging, and meet buyer specifications, ultimately maximizing profitability. For farmers, size measurement can provide valuable insights for future agronomic decisions.

2. The challenge: Detecting the undetectable

AVR wanted to develop a camera-based size measurement system to be installed on the bunker filling web of its Puma 4.0 harvester. The system was conceived to measure the length and width of potato samples in the product stream.

- Machine builders, not computer vision engineers: Although the AVR R&D team had a clear idea of what the system needed to do, the company lacked the expertise and knowhow to develop it. That's why AVR was looking for a reliable technology partner to work in close cooperation with the R&D team.

- Finding the right partner: "AVR not only wanted to develop a prototype, but also make the size measurement system production-ready," says Pieterjan Vanlaeken, Platform Leader Technology at AVR. "This could only be achieved in collaboration with a partner with a strong affinity with manufacturing."

3. The solution: Machine vision for anomaly detection

AVR enlisted Vintecc to co-develop a size measurement system for the Puma 4.0 self- propelled potato harvester. The system uses a stereovision cameras mounted on the bunker filling web to determine the potatoes' length and width during harvest. The benefit of stereovision is that this technology provides excellent depth estimation, which improves measurement accuracy.

- Size linked with location

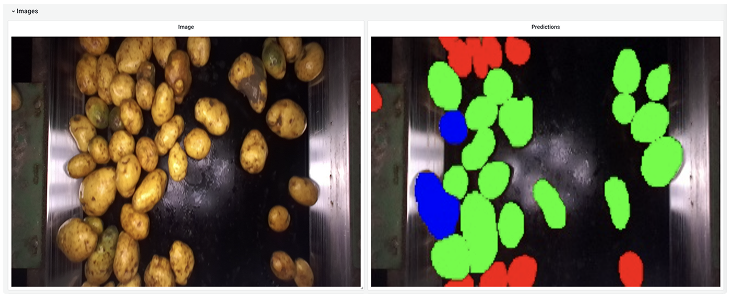

- The detection of potatoes is based on deep learning Al, which allows the system to recognize the potatoes in periodic sample images of the product stream. This in turn enables the system to select fully visible potatoes in the image for measuring their width and length.

- The size measurement data can also be linked with geolocation data, which offers growers the possibility to evaluate width and length of the measured potatoes for different harvested zones in their field. In other words, the AVR size measurement system provides a fully digital outlay of the width and length of the measured sample of the harvested potatoes.

- The detection of potatoes is based on deep learning Al, which allows the system to recognize the potatoes in periodic sample images of the product stream. This in turn enables the system to select fully visible potatoes in the image for measuring their width and length.

- Computer vision in challenging conditions

- Vintecc helped us to develop the system from the very start and really worked as an extension of our team," says Pieterjan Vanlaeken. "They selected the technology and handled the Al model training. Especially the stereovision technology was new to us. Vintecc helped us to get the most out of this technology, even in challenging lighting conditions."

- Vintecc helped us to develop the system from the very start and really worked as an extension of our team," says Pieterjan Vanlaeken. "They selected the technology and handled the Al model training. Especially the stereovision technology was new to us. Vintecc helped us to get the most out of this technology, even in challenging lighting conditions."

- Capture, an industrial loT platform

- The first prototypes of the size measurement system were monitored by means of Vintecc's proprietary loT platform Capture, which in this case collected valuable system data from the harvester in the field and made it available via the cloud for further evaluation by the R&D team.

- "Capture has been a great help during our first diagnosis and for debugging our first prototypes," says Pieterjan Vanlaeken. "Without this lot platform, we would never have been able to monitor the performance of our measurement system so efficiently."

- The first prototypes of the size measurement system were monitored by means of Vintecc's proprietary loT platform Capture, which in this case collected valuable system data from the harvester in the field and made it available via the cloud for further evaluation by the R&D team.

4. Key benefits of machine vision for anomaly detection:

AVR enlisted Vintecc to co-develop a size measurement system for the Puma 4.0 self- propelled potato harvester. The system uses a stereovision cameras mounted on the bunker filling web to determine the potatoes' length and width during harvest. The benefit of stereovision is that this technology provides excellent depth estimation, which improves measurement accuracy.

- Size linked with location

- The detection of potatoes is based on deep learning Al, which allows the system to recognize the potatoes in periodic sample images of the product stream. This in turn enables the system to select fully visible potatoes in the image for measuring their width and length.

- The size measurement data can also be linked with geolocation data, which offers growers the possibility to evaluate width and length of the measured potatoes for different harvested zones in their field. In other words, the AVR size measurement system provides a fully digital outlay of the width and length of the measured sample of the harvested potatoes.

- The detection of potatoes is based on deep learning Al, which allows the system to recognize the potatoes in periodic sample images of the product stream. This in turn enables the system to select fully visible potatoes in the image for measuring their width and length.

- Computer vision in challenging conditions

- Vintecc helped us to develop the system from the very start and really worked as an extension of our team," says Pieterjan Vanlaeken. "They selected the technology and handled the Al model training. Especially the stereovision technology was new to us. Vintecc helped us to get the most out of this technology, even in challenging lighting conditions."

- Vintecc helped us to develop the system from the very start and really worked as an extension of our team," says Pieterjan Vanlaeken. "They selected the technology and handled the Al model training. Especially the stereovision technology was new to us. Vintecc helped us to get the most out of this technology, even in challenging lighting conditions."

- Capture, an industrial loT platform

- The first prototypes of the size measurement system were monitored by means of Vintecc's proprietary loT platform Capture, which in this case collected valuable system data from the harvester in the field and made it available via the cloud for further evaluation by the R&D team.

- "Capture has been a great help during our first diagnosis and for debugging our first prototypes," says Pieterjan Vanlaeken. "Without this lot platform, we would never have been able to monitor the performance of our measurement system so efficiently."

- The first prototypes of the size measurement system were monitored by means of Vintecc's proprietary loT platform Capture, which in this case collected valuable system data from the harvester in the field and made it available via the cloud for further evaluation by the R&D team.

5. The result: Improved efficiency and product quality

The collaboration between Capture, Vintecc and Movu Robotics demonstrates how advanced technology can contribute to the optimisation of automated warehouses. By deploying smart algorithms, high-speed data logging and simulations via a Digital Twin, Movu Robotics was able to significantly improve the efficiency and scalability of their shuttle system.

This project highlights how innovative software solutions not only overcome technical challenges, but also contribute to cost savings and operational optimisation. Thanks to Capture, Movu Robotics is now ready for further growth and expansion in the world of warehouse automation.

An investment in precision and reliability

Movu Robotics, a leading player in warehouse automation, develops advanced systems for managing automated warehouses. Within this infrastructure, autonomous shuttles play a crucial role. They transport pallets between storage locations without human intervention, dramatically increasing efficiency and speed.

A core component in this system is the Advanced Stow Traffic Controller (ASTC), which is responsible for coordinating dozens of shuttles. To develop a reliable and scalable solution, Movu Robotics called on Vintecc (an integrator of Capture) to optimise the performance and efficiency of their system.

Watch the video

Want to discuss your anomaly

detection challenge?

Drop us a line. We probably have an answer to it.