Case Movu Robotics: Optimising automated warehouse traffic

global warehouse asset management

1. The big picture: a choreography of autonomous shuttles

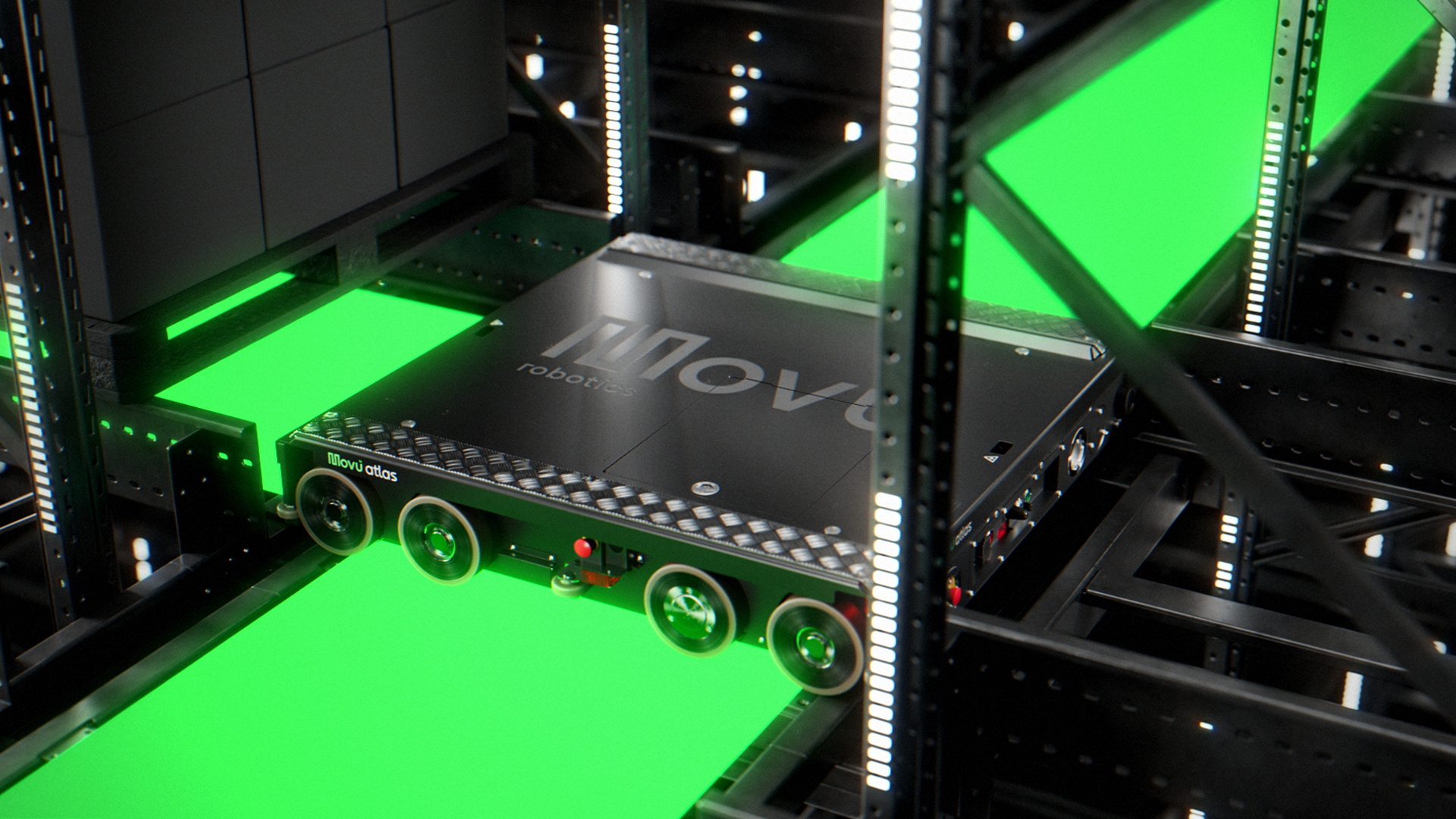

Movu Robotics, a leading player in warehouse automation, develops advanced systems for managing automated warehouses. Within this infrastructure, autonomous shuttles play a crucial role. They transport pallets between storage locations without human intervention, dramatically increasing efficiency and speed.

A core component in this system is the Advanced Stow Traffic Controller (ASTC), which is responsible for coordinating dozens of shuttles. To develop a reliable and scalable solution, Movu Robotics called on Vintecc (an integrator of Capture) to optimise the performance and efficiency of their system.

2. The challenge: Developing and optimizing a scalable and efficient traffic controller

Several challenges emerged when implementing a scalable and efficient ASTC:

- Scalability: The need to scale up from a limited number of autonomous shuttles to dozens without performance drops.

- Efficient route planning: Shuttles need to take the shortest route without conflicting with each other, similar to coordinating train traffic on a railway network.

- Limited computing power: Processing had to take place on on-premise systems, requiring algorithm optimisation rather than brute-force computing.

- Continuously changing requirements: Movu Robotics continues to innovate and expand, requiring a flexible and future-proof solution.

- Minimal downtime: Testing and implementing updates was not allowed to disrupt the continuity of warehouse management.

3. The solution: Data driven optimisation

Capture provided for Vintecc an advanced approach to optimise Movu Robotics' shuttle management:

- Advanced path planning algorithms: A state-of-the-art traffic control model was implemented, based on cutting-edge research. This enabled real-time optimisations.

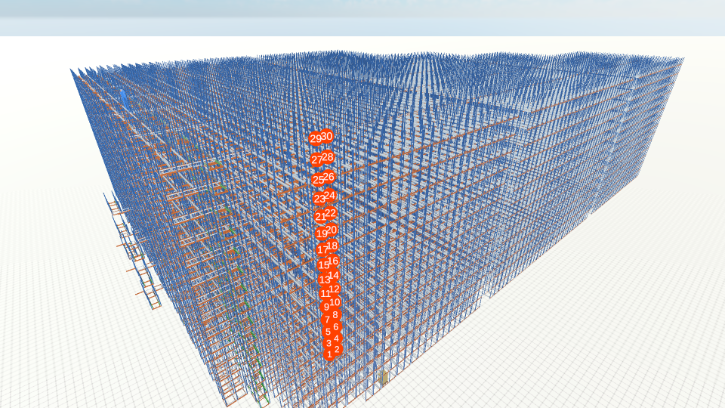

- Simulation via Digital Twin: Prior to on-site activation, all updates and optimisations were tested in a digital twin environment, allowing early identification of potential problems.

- High-speed data logging with Capture: The Capture platform was used to analyse real-time and historical data, allowing anomalies to be quickly identified and resolved.

- Efficient energy management: By strategically routing shuttles, battery consumption was minimised, which extended the life of the shuttles and optimised recharges.

- Cloud-based monitoring: Software updates could be tested and deployed remotely, reducing the need for technicians to make onsite interventions.

This combination of advanced software development and data-driven optimisations allowed Movu Robotics to significantly improve its shuttle operations.

4. The results: Higher throughput & lower costs

The implementation of Vintecc's solution in Capture delivered tangible benefits:

- Improved scalability: The system is optimised to manage up to 35 shuttles - and more - simultaneously without performance degradation.

- Faster and more efficient warehouse operations: Improved route planning allowed Movu Robotics to increase throughput and reduce shuttle downtime.

- Less downtime and faster troubleshooting: Capture and the Digital Twin allowed technical problems to be identified and resolved faster without physical intervention.

- Lower operational costs: Optimisations in battery management and remote software updates reduced maintenance costs and energy consumption.

- Flexible and future-proof solution: The ASTC can now easily handle new warehouse configurations and customer requirements.

5. What's next

The collaboration between Capture, Vintecc and Movu Robotics demonstrates how advanced technology can contribute to the optimisation of automated warehouses. By deploying smart algorithms, high-speed data logging and simulations via a Digital Twin, Movu Robotics was able to significantly improve the efficiency and scalability of their shuttle system.

This project highlights how innovative software solutions not only overcome technical challenges, but also contribute to cost savings and operational optimisation. Thanks to Capture, Movu Robotics is now ready for further growth and expansion in the world of warehouse automation.

Want to discuss your advanced planning challenge?

Drop us a line. We probably have an answer to it.