At Capture, we see industrial companies with solar panels struggling with highly dynamic energy prices. Precise, data-driven energy management becomes essential in sectors where consumption patterns can change rapidly, whether due to varying production schedules, batch processes, or seasonal demand. In this blog, we dive deeper into the technical foundation of our Energy Monitoring System (EMS) and how it transforms these challenges into tangible opportunities for efficiency and cost savings.

Solar Panels on the roof

1. Why injection isn’t always a good idea

Photovoltaic (PV) arrays often reach their maximum output during midday, possibly coinciding with periods of reduced industrial load. Without a control strategy, this surplus energy would be exported to the grid. In regions with high renewable penetration, the market can become oversupplied, causing day-ahead and imbalance prices to turn negative. In such cases, facilities can find themselves paying to inject electricity. A counterintuitive and costly outcome. These price events can happen frequently enough to erode the economic benefits of solar investments.

Price evolution: every hour different injection (green) and consumption (grey) prices

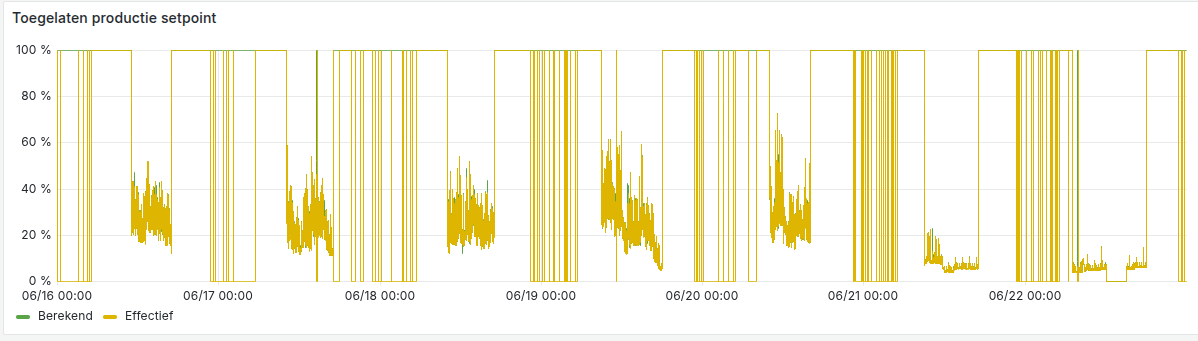

2. The role of smart energy management

Dynamic control is not a static on/off switch. It’s a continuous, adaptive process that monitors live market prices alongside site-specific load profiles. Our EMS implements solar curtailment strategies, actively modulating inverter output so that generation matches the most cost-effective option at any given moment. When prices are high or neutral, the inverters are modulated at maximum capacity; when prices are low or negative, production is automatically reduced to align with internal consumption. This real-time adaptability ensures the system maximizes profitability over the course of the day, not just at peak production moments.

Maximum allowed PV production

3. How our EMS makes the difference

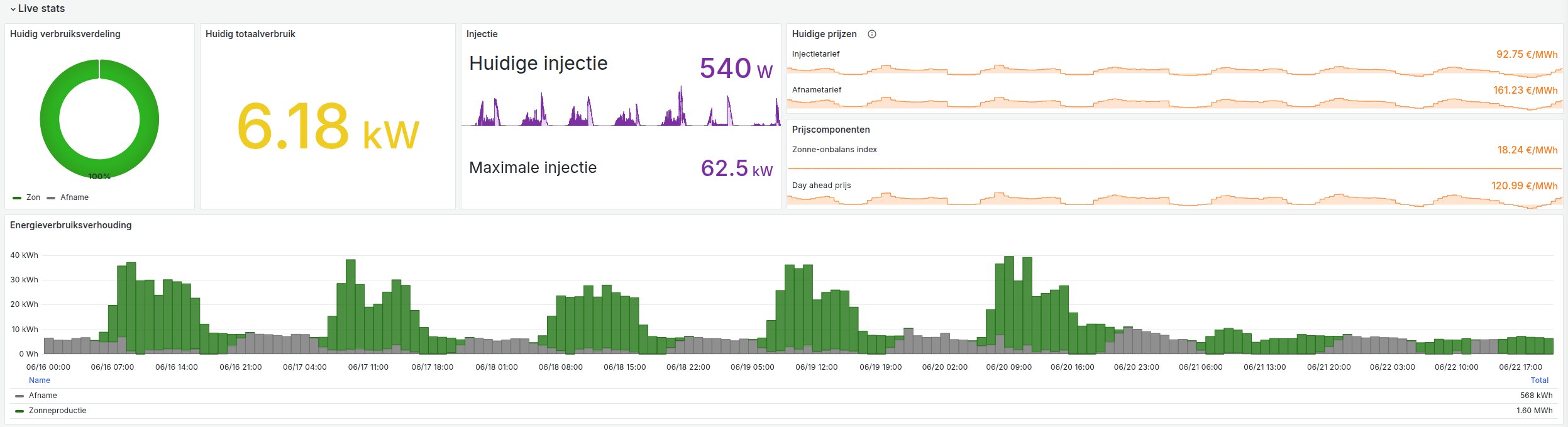

At the heart of our EMS lies a high-speed control loop, executing every 3–5 seconds. It integrates data from multiple critical sources:

- On-site metering: capturing high-resolution consumption and PV output readings to ensure accuracy in real-time decision-making.

- Market interfaces: pulling in day-ahead pricing and live imbalance prices.

- System configuration: embedding contract-specific parameters, operational limits, and inverter capabilities.

The control logic follows a robust decision-making sequence:

- Aggregate and normalize all incoming data streams.

- Calculate the marginal economic value of exporting versus curtailing.

- Issue updated inverter setpoints via secure API or industrial communication protocols (e.g., Modbus, fieldbus).

- Record all actions and system states to support ongoing optimization and auditability.

Deployment involves:

- Installing and commissioning a local control unit with secure, encrypted communication to the Capture cloud.

- Integrating with inverters from leading manufacturers such as SMA, Huawei, and Fronius trough industrial communication protocols such as Modbus.

- Calibrating the control logic to match contract terms and operational boundaries.

- Running validation phases to compare against baseline performance before live operation.

General statistics of our EMS system

4. Tailored to your energy contract

Our EMS is fully customizable to align with different tariff structures: fixed-rate, variable-rate or fully dynamic. By tying inverter behavior directly to your energy supplier’s price triggers, we make sure every curtailment action has a net positive impact.

5. The benefits at a glance

With our EMS, clients benefit from:

Significant reduction in exposure to negative pricing events.

Ultra-responsive setpoint control while optimizing energy costs.

Comprehensive dashboards showing live KPIs, historical trends, and predictive analytics.

A modular design that extends beyond PV control to manage EV charging, HVAC, and process loads.

Proven deployment success across industrial clients.

6. Beyond solar panels

The same control framework that optimizes solar output can also orchestrate broader energy ecosystems. In the future, our EMS could shift EV fleet charging during low-price periods, pre-cool or pre-heat HVAC systems to move demand away from peak tariffs, and manage process loads in manufacturing environments by leveraging thermal or batch storage. This flexibility transforms the EMS into a comprehensive load management tool, enhancing profitability.

7. Take the next step

In today’s volatile energy markets, smarter energy use is not a luxury. It’s a strategic necessity. Our EMS provides the closed-loop control, real-time market intelligence, and operational insights required to unlock maximum efficiency. Get in touch with our experts to model your potential savings and design a system that’s precisely tuned to your site’s unique operational profile.